Wafer Foundry Services

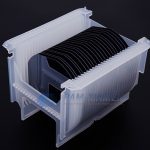

Semiconductor foundry service according to customer demand designs and manufactures wafer from small quantity into production. Wafer foundry services of Ganwafer are offered for micro-electrical mechanical systems (MEMS), power electronics, sensors, microprocessors and etc. Our semiconductor foundry business is all over the world for electronic equipment manufacturers, research institutions, universities and so on. Semiconductor foundry process of Ganwafer includes chemical mechanical polishing (CMP), physical vapor deposition (PVD), chemical vapor deposition (CVD), screen printing, dry etching, wet etching, photolithography, wafer-scale packaging, and other processes.

- Description

- Inquiry

Description

Semiconductor foundry process is the process from raw wafer to semiconductor chip. Traditional wafer foundry services refer to the processing steps for transistors, resistors and other electronic components, which are fabricated on wafers.

1. Semiconductor Foundry Services

Our semiconductor foundry offers full-service for you:

– MEMS Two-Dimensional Material Integration Service;

– Polyimide Process;

– Wafer Etching Process;

– Coating Process;

– Photolithography Process;

– Wafer Bonding, etc.

2. Semiconductor Foundry Capacity

| Process Name | Wafer size(inch) | Capability |

| Stepper Photolithography | 6 | 0.40um |

| Contacted Photolithography | 2,4 | 3um |

| Dry etching | 6 | Depth 100um(Si), metal, GaN |

| Wet bench | 6,8 | Metal, SiO2, SiN, TEOS, poly-silicon |

| PECVD | 6 | SiN SiO2.TEOS |

| LPCVD | 6 | SiN, SiO2.poly- silicon |

| ALD | 6 | Al2O3, AIN |

| Sputter | 6 | Ti, Al, TiN, Ni, W, TiW, WN |

| E-beam | 4,6,8 | Ti, Ni, Ag, Al, Ta,Cr, Pt, Mo, Co |

| Implantation | 6 | B(20- 200KeV,1E13-1E15), N |

| RTP | 6 | 900C max. |

| Oven | 6 | 400C max. |

In addition, as one of semiconductor foundry companies, we provide manufacturing services with single step and multiple steps for semiconductor devices of MEMS, GaAs and etc. We possess advanced micro-nano design technology, reaching global level. Also almost all kinds of wafers from semiconductor foundries can meets customers’ demands for fabrication devices in different applications.