Ganwafer offers semiconductor silicon carbide (SiC) substrate and silicon carbide wafer epitaxy with polytype of 6H and 4H. We have different quality grades to meet the demands of researchers and industry manufacturers.

We have developed the advanced silicon carbide crystal growth technology and silicon carbide wafer manufacturing process that helps to produce silicon carbide substrate and silicon carbide epitaxy. The SiC substrate is used in optoelectronics, power devices, high-temperature devices as well as GaN epitaxy devices. While SiC epitaxial wafer is for fabricating bipolar junction transistors (BJT), Gate Turn-off Thyristor (GTO), insulated gate bipolar transistor (IGBT), metal-oxide semiconductor field-effect transistors (MOSFET), junction field effect transistors (JFETs) and Schottky diodes.

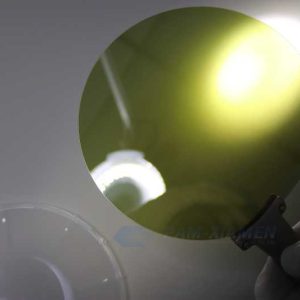

What is a SiC Wafer?

Silicon carbide wafer is a next-generation semiconductor material typically and it features electrical properties and outstanding thermal properties. Most importantly, bare silicon carbide wafer is appropriate for high temperature and high power device applications. Since silicon carbide can dope with n-type or p-type in the range of over 5 magnitude orders without effort, it is the best material in the wide bandgap semiconductors.

It is the only compound semiconductor because of its physical and electronic properties that make silicon carbide wafer growth suitable for short-wavelength optoelectronic, high temperature, radiation-resistant, and high-power/high-frequency electronic devices. As an insulator, it is possible to make the complete electronic device based on metal oxide semiconductor group with silicon carbide substrate.

The hardness of silicon carbide wafer production is another factor that offers the material several benefits, in high speed, high temperature, and/or high voltage applications.

As one of leading silicon carbide wafer manufacturers from the fields of advanced and high-tech material research and state institutes and China’s Semiconductor Lab, we are committed to unceasingly enhance the quality of current substrates and develop large size SiC substrates.